Your concern. Our response.

How to ensure fast and efficient recalls?

John, Q&R

John's concerns

We have low visibility on where our assets are. When we need to find one given instrument, it’s like finding a pin in a haystack. A few years ago, we had to recall an instrument for patient safety reasons, and it took us more than a year to finally find it and execute the recall.

We were relying on the data uploaded by sales reps into our ERP, which was too often incomplete or incorrect... and it was just impossible to get the full picture.

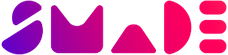

Impossible? Not with SMADE!

Our response

With SMADE digital ID, lot numbers and location tracking features, you will know exactly where your trays are, at any given time. With the tray content check RFID functionalities, you will also be able to track and identify the instruments inside your trays. Hence SMADE will make it possible to execute any recall, quickly and smoothly. For even greater patient safety, SMADE will record the full history of utilization and geolocation of your instruments and trays, in full autonomy, no human intervention needed.

Digital ID

Activity tracker

Location tracking

Inventory cycle count

Tray content check

Last location communicated

Autoclave count /period

Drop & impact tracker

Location history

Drop & impact history

Spot incomplete trays

Guarantee patient safety

Execute recalls in a timely manner