-

What is SMADE?

SMADE is an IoT* technology that offers a range of smart asset tracking solutions for OEMs. SMADE solutions allow OEMs to track key metrics on their surgical trays and instruments, such as the number of autoclave cycles or geolocation, without the need for any human intervention.

SMADE solutions allow for smoother operations, optimized inventory management, data-driven marketing recommendations, higher Q&R compliance, and overall higher patient safety.*Internet of Things – the interconnection via the internet of computing devices embedded in everyday objects, enabling them to send and receive data.

-

How does SMADE asset tracking solutions work?

SMADE trackers are installed into your assets (totes, trays, sterilization containers, instruments, etc.). There, they collect a wide range of data points (location, washing, autoclaving, drops, etc.), and send it to S-HUB, SMADE proprietary analytics platform, autonomously.

Finally, S-HUB translates your field data into visual analytics, to empower your decision making and optimize your inventory management.

-

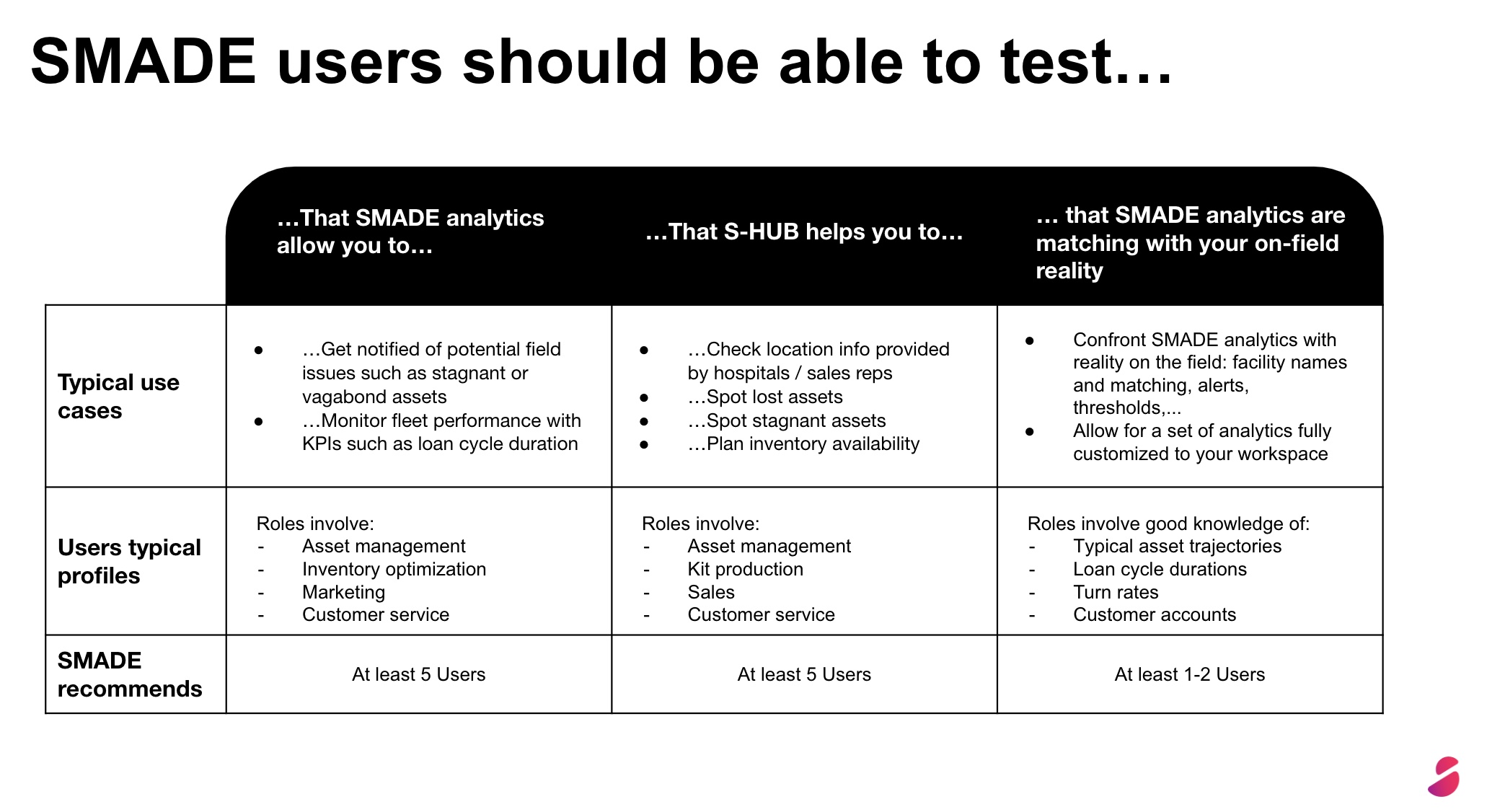

What is S-HUB?

S-HUB is SMADE proprietary digital platform that receives, analyzes, and reports the field data collected by SMADE trackers. Depending on their SMADE subscription, S-HUB users can log into their S-HUB account to locate their assets on a map, to have a daily update of what happened to their connected assets in the past 24 hours, or to access exhaustive analytics reporting that help them make data-driven decisions.

-

What does “proprietary” mean?

Both SMADE hardware (the trackers) and software (S-HUB) are proprietary. All our technologies have been developed at SMADE, and we own everything down the process. This means we can adapt to specific user needs, and work on enhancing the performance of our devices or custom our platform as needed.

-

Where is SMADE located?

SMADE HQ is located in Lyon, France.

-

Are SMADE solutions available in all markets?

SMADE solutions are compatible with most markets where OEMs operate. They work in all North-American and European markets, and several other markets around the globe. Specific requests should be looked upon.

-

Who can you reach out to for more information?

Please tell us who you are and how we can help you here! We will be in touch with you shortly.

-

Can SMADE trackers collect data everywhere?

SMADE trackers can collect data in all targeted markets (North-American and European countries namely).

SMADE provides a high level of connectivity within targeted markets, which means that data will be transmitted to S-HUB in full autonomy in most locations.

In case of poor connectivity in a given location, SMADE trackers still collect data and keep it in a backup memory, so all events can be retrieved when connectivity is back.

SMADE trackers are designed and optimized to function in harsh environments but external factors such as the local configuration and operator coverage robustness can affect their connectivity to the network hence their battery life.

-

What is the difference between the three SMADE location trackers?

All our location trackers provide the same set of features, including a 50-meter specific location information for your assets. Here are the differences between LC01, LC02, and LC03:

LC01 is a cold location tracker. It is meant to track location of any asset that does not go into sterilization or is already sterilized, such as implants for instance. It is the only SMADE tracker that is not meant to go through a full cleaning process, and can only be used with already sterilized assets, or any asset that does not go into autoclaving (e.g., sterile implants, demo material, capital equipment).

LC02 is a location tracker, small size. It is the smallest and lightest SMADE tracker for autoclavable assets that has been designed.

LC03 is a location tracker, normal size. It is the normal-sized location tracker for autoclavable assets.

-

Can SMADE technology be embedded in an OEM instrument or asset?

Yes! SMADE has created “SMADE inside”, an agile and collaborative process that elevates your assets to smart devices by embedding SMADE advanced tech in any existing trays and/or instruments.

SMADE would need to work closely with the OEM product development team to jointly design an insert and the associated electronic layout. Design would need to take into account the battery placement, the sensor(s) position(s) and the wireless communication antennas. SMADE would also provide guidelines from its expertise on sealing to ensure the electronic board is perfectly safe.

-

What should I do upon receiving the trackers?

We recommend taking your trackers out of their packaging 24 hours in advance of installation. This helps ensure smooth setup, quick network connection and optimal performance. Pair your trackers with your assets upon receipt to send them to the field and start collecting your data. If you need assistance getting started with your tracking experience, please contact your onboarding specialist who will be happy to assist you (mettre un mailto vers mike@smade.io)

-

Can tracker transmission be stopped?

It’s possible that your trackers are taking a short break, snoozing for 24 to 48 hours. Don’t worry, though, data is still being captured and will be back on track as soon as they wake up!

-

What if the signal has been lost?

If the signal has been lost for more than 3 days: it seems like your trackers are going through some unusual behavior, possibly due to a weak or unavailable network coverage. We’re here to help troubleshoot and find a solution.

If the signal has been lost for more than 5 days: let’s have a quick chat to better understand what’s going on. Rest assured, we’re committed to replacing any affected trackers and getting things back to normal.